MetacoteTM Metallized EMI-ESD Shielding Solutions

For Defense and Space - Think Material

Precision. Protection. Performance.

As modern warfare and space missions become more technology-driven, electromagnetic interference (EMI) is emerging as a critical concern. Today’s defense and aerospace platforms are increasingly reliant on compact, high-density electronics — integrating AI processors, high-frequency sensors, satellite links, radar, and communications gear into smaller, mission critical platforms.

But with this advancement comes a sharp rise in electromagnetic interference (EMI) – both from within and from the environment. Even minor EMI can lead to signal loss or corruption, system malfunction or detection, and mission critical failure.

Unlike commercial electronics, the systems in defense and space require high-performance EMI shielding solutions that are lightweight, flexible or conformable, highly durable, and capable of maintaining performance over a wide frequency range, even under harsh conditions.

Yet, traditional shielding solutions haven’t kept up with these demands. They’re bulky, inflexible, and often suffer performance drop-offs at higher frequencies or under mechanical, thermal, or environmental stress. They can also be expensive and have longer lead times.

Metallized Solutions.

Built Different. Performs Better.

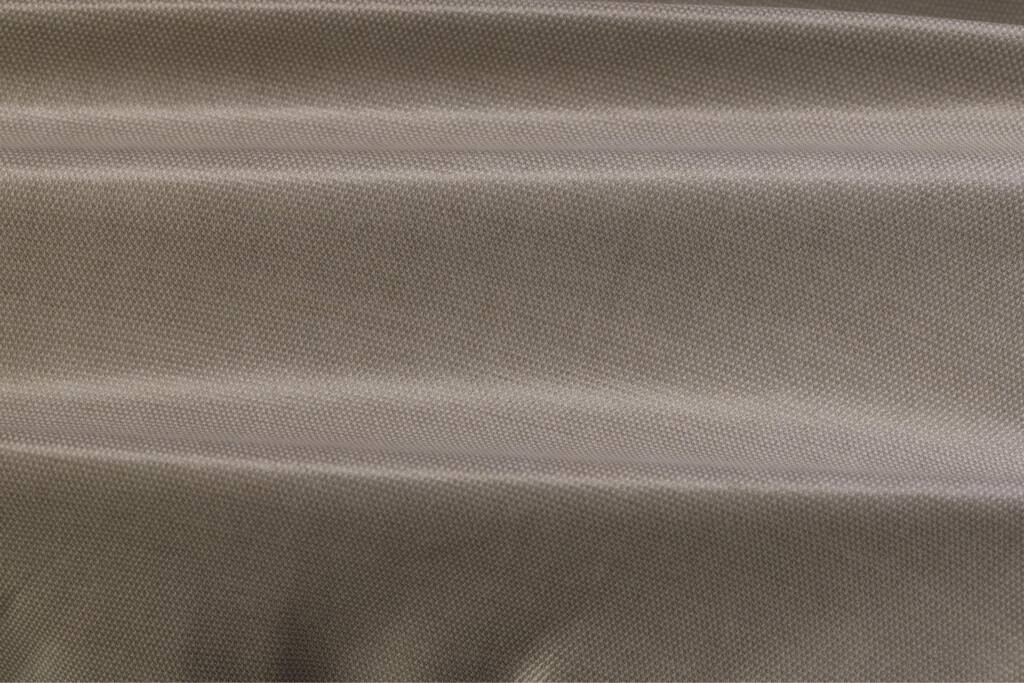

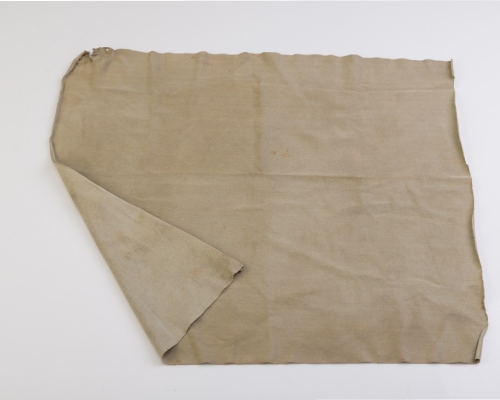

Metacote™ is a defense- and space-grade EMI shielding solution engineered to meet the most rigorous environmental, frequency, and mechanical demands. At its core is our proprietary metallization process, where a robust covalent bond is created between the substrate and 99.9% pure silver.

Silver—the most electrically conductive metal, enables exceptional EMI shielding performance, across a wide range of frequencies. The ability to custom produce various products based on specific applications brings that power at an affordable price point. It can be made into thin, flexible, and durable high-performance materials designed to withstand mechanical wear and extreme environmental stress.

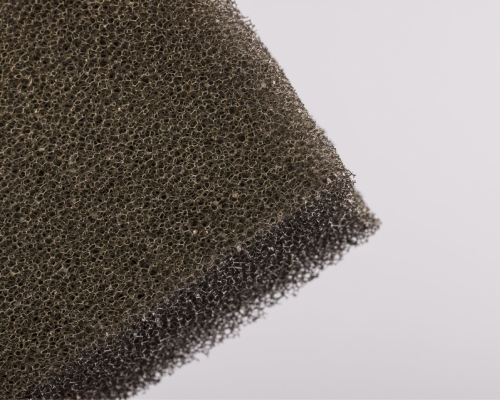

This advanced metallization process can be applied to filament yarns, fabrics, polymeric foams, staple fibers, spun yarns, chopped fibers, and particles—offering exceptional versatility. Our yarns can be woven/ knitted into fabrics at different construction levels or can be metallized fully over the fabrics.

Apart from silver, we’ve also engineered multi metal combinations such as silver over nickel, copper-nickel metallization etc. This combines the strengths of multiple metals, metallized over one another enhancing the properties depending on application and ensuring compliance, durability, and weight optimization.

KEY FEATURES

- Ultra-high shielding effectiveness (>100 dB) across wide frequency ranges (kHz to GHz)

- Thin, lightweight, compact and flexible for maximum design adaptability

- Consistent shielding performance under thermal cycling and other durability tests

- IR shielding for thermal camouflage and radiation reflection

- High electrical conductivity for effective EMI suppression

- High anti-static protection with faster static dissipation

- Anti-microbial properties — useful in field gear and uniforms, supporting hygiene and wound healing

- Seamless integration into body-worn gear, satellite interiors, or embedded electronics

- Designed to withstand harsh

environments – from battlefield to vacuum.

Made in India at our R&D-backed manufacturing facility (ISO 9001: 2015 certified), we control the entire metallization journey, ensuring quality, agility, and customization at scale.

OUR PRODUCT PORTFOLIO

Filament Yarn | Silver

Fabrics | Silver | Copper-Nickel | Nickel

Polymeric Foams | Silver | Copper-Nickel

Particles | Silver over Nickel | Silver over Copper | Nickel over Graphite | Silver over Aluminium

Films

Chopped Fibers

APPLICATIONS

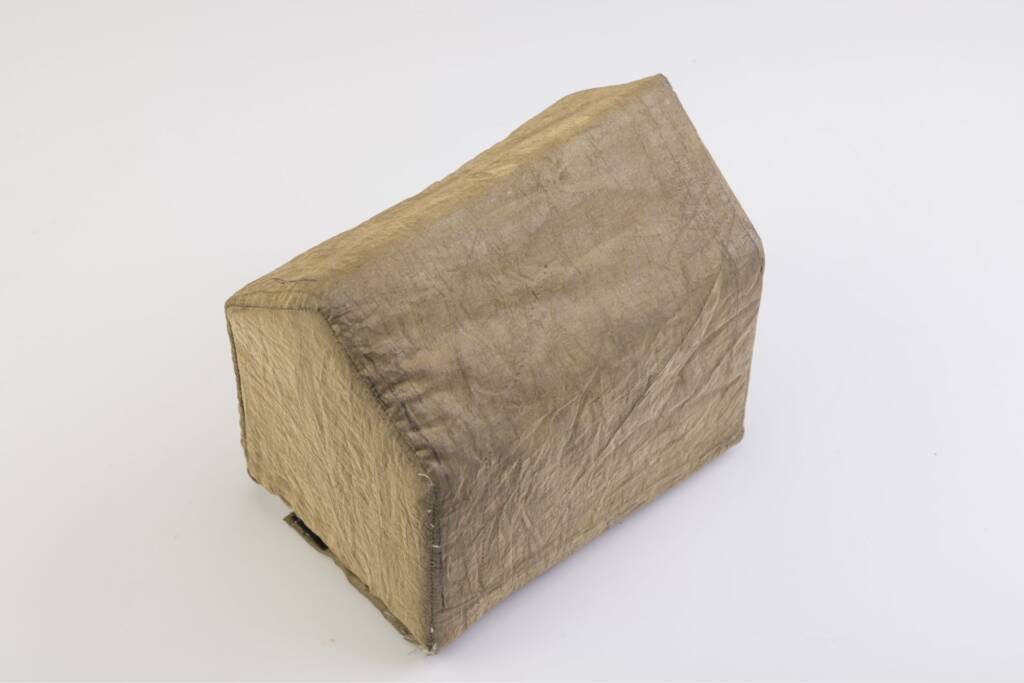

Military Communication Systems (e.g., manpacks, tactical radios)

Avionics & Radar Modules

Electronic Warfare (EW) Components

Satellite Structures and Payloads

Launch Vehicle Electronics & Interconnects

Ground Support, Tracking & Navigation Systems

UAVs, Drones, and Autonomous Defense Platforms

IR-Camouflage and Sensor Shielding in Soldier Gear

Wearable Soldier Systems

Thermal Blankets, Wraps, Shields

PERFORMANCE SNAPSHOT

Our products have been tested at multiple test houses and have demonstrated exceptional results, which can be further customized as per the requirements.

- Conductive Fabrics demonstrated high shielding effectiveness up to 110 dB across 200 MHz to 18 GHz, and over 70 dB for frequencies greater than 18 GHz. These fabrics can be further enhanced from a shielding performance point of view, if the need arises.

- Copper-Nickel-metallized Conductive Foams achieved 110–120 dB shielding up to 10 GHz, with sustained performance of 70 80 dB at 18 GHz and higher.

- Silver-metallized Conductive Foams delivered exceptional results at high frequencies of 18–110 GHz.

- Product robustness was showcased when exposed to extreme temperature variations and are also highly durable.

- Thermal regulation properties were showcased, with enhanced heat distribution and stable conductivity.

CUSTOM SHIELDING SOLUTIONS, BUILT AROUND YOUR SPECS

STEP 1

Share Your Needs

Share your shielding requirements – frequency range, form factor, integration constraints.

STEP 2

Receive Sample kit

Purchase an appropriate shielding sample suited to your application need.

STEP 3

Performance Evaluation

Evaluate performance on your equipment or in your environment – real data, real results.

STEP 4

Refine The Design

Based on feedback, we iterate to deliver the product to your specifications.

STEP 5

Approve & Order

Move to production with solutions proven in your context.

Get In touch

Contact info

Address: No. 61, 3rd Floor, 5th Block, Koramangala, Bengaluru, Karnataka 560095

Email : info@fiberse.com

Number : 1800 103 8655

DISCOVER YOUR PERFECT SHIELDING SOLUTION WITH US

Whether you re shielding a satellite’s onboard electronics, a missile’s guidance system, or advanced soldier gear, Metacote™ delivers reliability without compromise. We deliver the solution that meets your spec today.